Another Innovative new development from Nordinkraft, The NORDISCAN-RAIL is our platform of Ultrasonic inspection systems designed for the detection of internal and surface defects in Railroad rails which inspects the head, web, and foot using our state-of-the-art Ultrasonic Phased Array and EMAT probes.

These systems open a new chapter in Nordinkraft’s history by entering the Rail inspection business. This is made possible due to the forward-thinking professionalism of our engineers, discipline of our managers, and deep trust of our Customers.

Depending on the testing task, NORDISCAN-RAIL can be provided in to three different configurations:

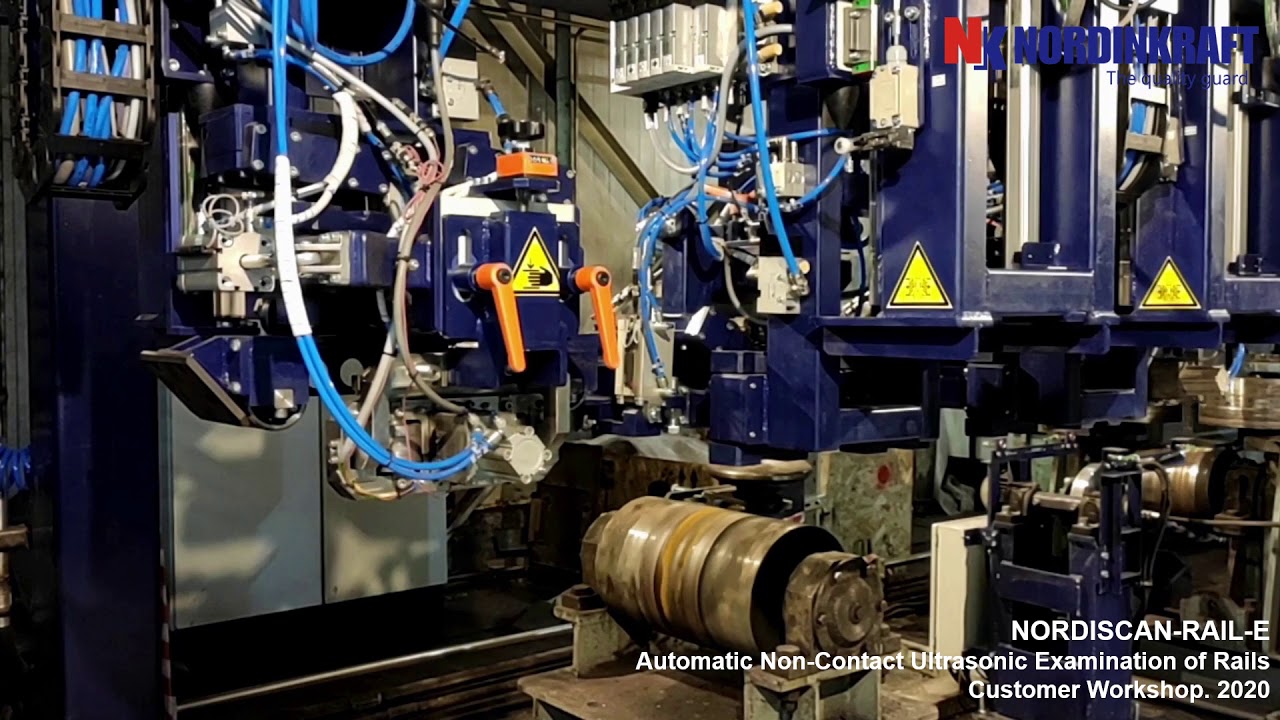

NORDISCAN-RAIL-E. The system is intended for the detection of internal defects in rails head, neck, and foot

using our state-of-the-art EMAT probes in pass-though and echo modes.

NORDISCAN-RAIL-S – immersion UT system for detection of surface defects on rails. Overall configuration of this system is based on “pass-through” concept, applied previously for NORDISCAN-BB, it means that rail will pass throng the water tank with the set of phased array probes intended for 100% coverage of the rail surface. No more static and rotating EC probes, no more water jet probes – no wasting of time for re-adjustments.

NORDISCAN-RAIL-I – also immersion system for detection of internal imperfections in rail (head, neck, and foot), with the highest accuracy, reliability and on the speed up to 2 m/s.

Upon the Customer request NORDISCAN-RAIL systems can be supplemented with additional peripheral systems for high-precision measurement of geometric dimensions of control objects as well as marking, sorting, and packaging.

Another Innovative new development from Nordinkraft, The NORDISCAN-RAIL is our platform of Ultrasonic inspection systems designed for the detection of internal and surface defects in Railroad rails which inspects the head, web, and foot using our state-of-the-art Ultrasonic Phased Array and EMAT probes.

These systems open a new chapter in Nordinkraft’s history by entering the Rail inspection business. This is made possible due to the forward-thinking professionalism of our engineers, discipline of our managers, and deep trust of our Customers.

Depending on the testing task, NORDISCAN-RAIL can pe provided in to three different configurations:

NORDISCAN-RAIL-E. The system is intended for the detection of internal defects in rails head, neck, and foot

using our state-of-the-art EMAT probes in pass-though and echo modes.

NORDISCAN-RAIL-S – first immersion UT system for detection for the examination of rail surface. Overall configuration of this system is based on “pass-through” concept, applied previously for NORDISCAN-BB, it means that rail will pass throng the winter tank with the set of phased array probes intended for 100% coverage of the rail surface. No more static and rotating EC probes, no more water jet probes – no wasting of time for re-adjustments.

NORDISCAN-RAIL-I – also immersion system for detection of internal imperfections in rail (head, neck, and foot), with the highest accuracy, reliability and on the speed up to 2 m/s.

Upon the Customer request NORDISCAN-RAIL systems can be supplemented with additional peripheral systems for high-precision measurement of geometric dimensions of control objects as well as marking, sorting, and packaging.

Typical Specification of Rails to be Tested:

- Type of the Rails: Р50, Р65, Р75, ОР50, ОР65, 60Е1А1, 54Е1А1, 54Е1А2, 49Е1А2 49Е1, 49Е2, 54E1, 50Е6, 60E1, 60E2

-

Material: carbon steel and its alloys

Ultrasonic Testing Standards:

Density of Ultrasonic examination, test procedures, acceptance criteria, data processing and representation adhere to multiple international and local railway standards such as: GOST R 51685-2013 и GOST R 55820-2013, AREMA and EN-standards.