NORDISCAN-BB systems are intended for examination of bars, billets, and other more complex profiles. Depending on the testing task, we apply two basic configurations of NORDISCAN-BB:

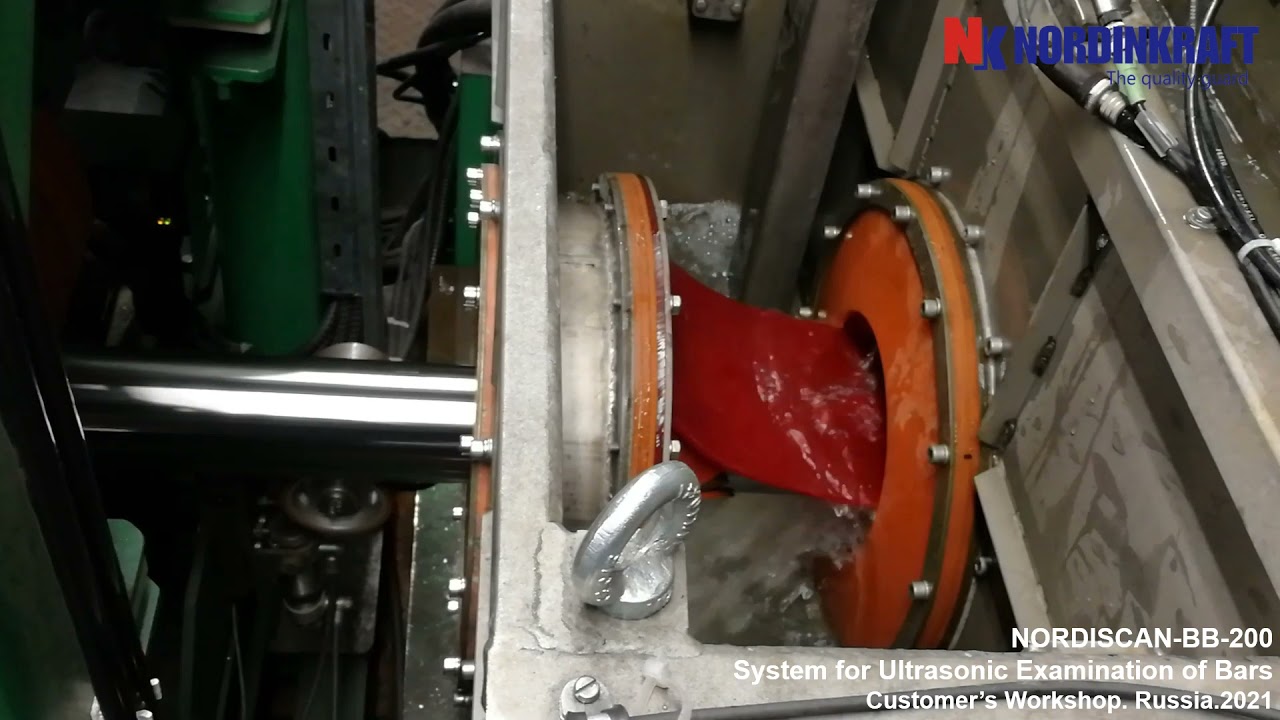

- For examination of bars of small diameters, billets, profiles, and rail we are applying a “pass-through” configuration based on providing a dedicated immersion tank with the probes submerged in it. Efficient seals on the input and output ensure minimal loss of water and continuous inspection capability. Such configuration is nearly invisible to the production line with testing speeds up to 2 m/s, and with the application of phased-array methods provides increased flexibility for different test objects and tasks.

- The “gantry” configuration of NORDISCAN-BB is used for testing large diameter round bars. In this configuration, the measuring module with a set of ultrasonic transducers moves along the length of the product being inspected from above the bar, along the bar length while the bar is rotating below, providing efficient 100% scanning in a helical pattern.

Regardless of the configuration, installations of the NORDISCAN-BB series are equipped with various types of ultrasonic transducers which significantly expands the potential installation locations possible and endless tasks can be solved.

The NORDISCAN-BB series achieves multiple

inspection tasks:

-

Detection of inner defects, like shrink holes, insulation, blowholes, inclusions, etc;

-

Detection of surface and sub-surface defects.

Typical Specification of Bars to be Tested:

-

Diameters: 5 mm – 1000 mm;

-

Length: from 1000 mm;

-

Material: carbon steel.

Main Ultrasonic Testing Parameters

- Test Sensitivity:

- For internal imperfections: equal to FBH 0.4*;

- For surface imperfections: equal to notches 0.2 mm x 10 mm (D x W);

- Testing Speed: up to 2 m/s.

*Depending of material to be tested

Type of Applied Multichannel Ultrasonic or Eddy Current probes:

-

Non-contact array probes, based on the EMAT;

-

UT phase array probes;

-

UT probes with the array of piezo-crystals;

-

Eddy-current probes.

Ultrasonic Testing Standards:

Density of Ultrasonic examination, test procedures, acceptance criteria, data processing and representation adhere to multiple international and local standards such as: ISO 18563, AMS2154, EN 10308; EN 10228; GBT 4162, GBT 5777, SEP and GOST family standards.

Testing and acceptance criteria can be customized based on client specific needs and new standards.