Hard Spots are areas with irregular hardness normally occurring on the production line from the hot rolling process of plates, also referred to as bruises. These areas of local hardening variances become a source of mechanical stress after forming plates into line pipes (LSAW or HSAW). Being invisible by the conventional UT or X-ray methods Hard Spots might cause the occurrence of small microcracks under the constant and in-process cyclic loads that pipelines experience, which are caused by dislocations and slip bands creating potentially expedited fatigue, cracking and failure ending catastrophically in leaks or explosions.

Detection of hard spots at the early production stage can save a lot of money, working hours, and most importantly, the environment, human lives and livelihoods. After recognizing the market need for an efficient tool for reliable and high-capacity inspection of Flats for detection of Hard Spots, Nordinkraft have actively engaged in new solutions and product developments in this area and now introduce EddySpot – first in the world system for automatic non-contact detection of Hard Sports.

Depending on the testing task, we apply several basic configurations of EddySpot:

EddySpot-Desktop – single-probe desktop automatic scanner intended for examination of the material properties for the research and development lab purposes. EddySpot-Desktop is the perfect instrument, which allows fast and

“human-factor-free” acquisition of test result as a X-Y plot.

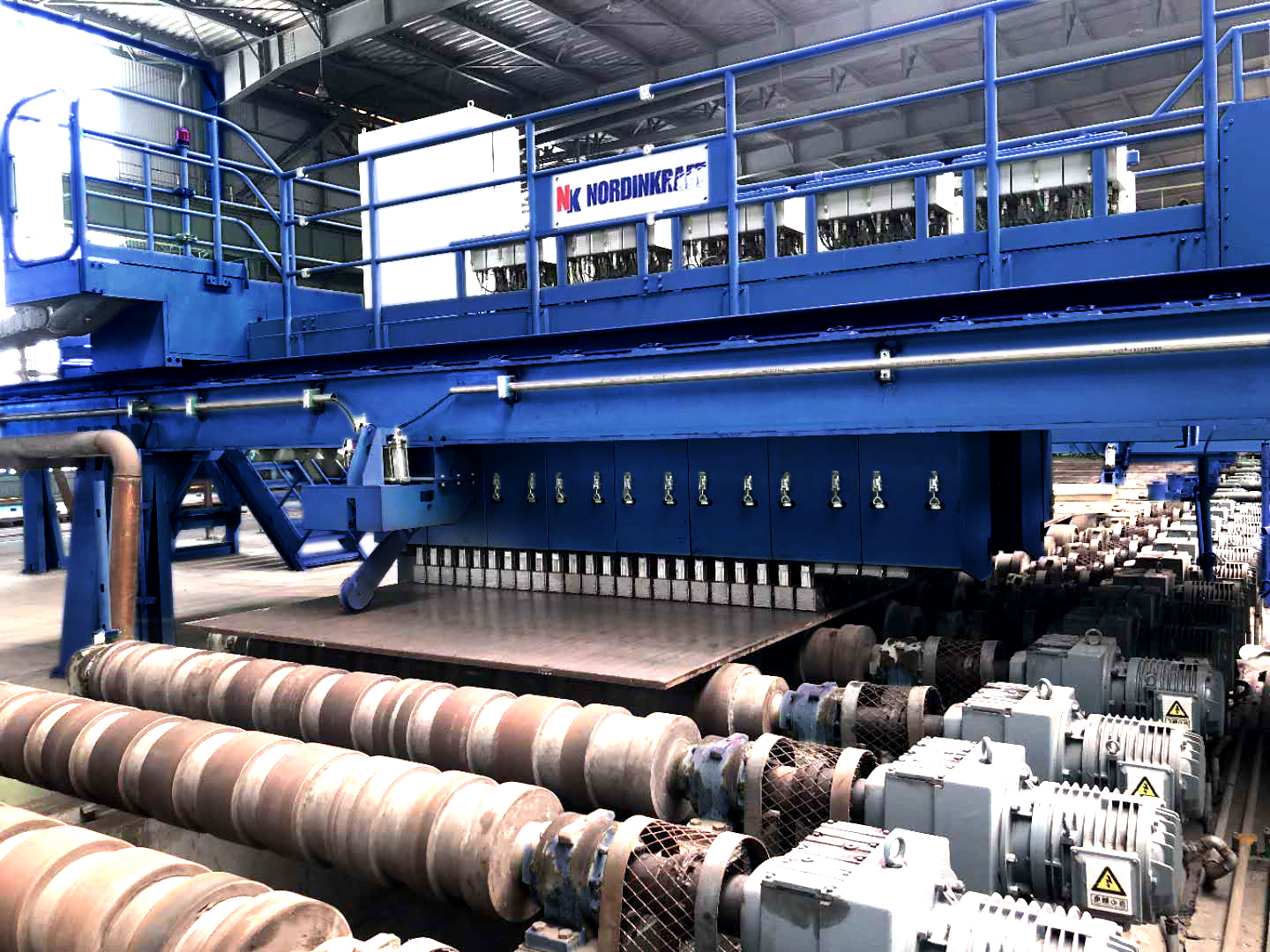

EddyScan-PL – System based on application of NORDISCAN-PL mechanics but equipped with a set of our patented Eddy Current probes for reliable off-line inspection of plates for Hard Spots.

EddySpot-PL– System which uses the configuration of EMATEST-PL as a basis but instead of lines of EMAT or Phased Array probes we apply lines of pantented EddyCurent probes. EddySpot -PL is the most sophisticated system intended to perform in-line examination of plates for HardSpots at speeds of up to 2 m/s. Both sides of the plate can be tested simultaneously.

Hard Spots are areas with irregular hardness normally occurring on the production line from the hot rolling process of plates, also referred to as bruises. These areas of local hardening variances become a source of mechanical stress after forming plates into line pipes (LSAW or HSAW). Being invisible by the conventional UT or X-ray methods Hard Spots might cause the occurrence of small microcracks under the constant and in-process cyclic loads that pipelines experience, which are caused by dislocations and slip bands creating potentially expedited fatigue, cracking and failure ending catastrophically in leaks or explosions.

Detection of hard spots at the early production stage can save a lot of money, working hours, and most importantly, the environment, human lives and livelihoods. After recognizing the market need for an efficient tool for reliable and high-capacity inspection of Flats for detection of Hard Spots, Nordinkraft have actively engaged in new solutions and product developments in this area and now introduce EddySpot – first in the world system for automatic non-contact detection of Hard Sports.

Depending on the testing task, we apply several basic configurations of EddySpot:

EddySpot-Desktop – desktop single-probe desktop automatic scanner intended for examination of the material properties for the research and development lab purposes. EddySpot-Desktop is the perfect instrument, which allows fast and

“human-factor-free” acquisition of test result as a X-Y plot.

EddyScan-PL – System based on application of NORDISCAN-PL mechanics but equipped with a set of our patented Eddy Current probes for reliable off-line inspection of plates for Hard Spots.

EddySpot-PL– System which uses the configuration of EMATEST-PL as a basis but instead of lines of EddyCurent probes we apply lines of EMAT Ultrasonic probes. EddySpot -PL is the most sophisticated system intended to perform in-line examination of plates for HardSpots at speeds of up to 2 m/s. Both sides of the plate can be tested simultaneously.

Typical Specification of Plates to be Tested:

-

Width: 100 mm – 6000 mm

-

Length: from 100 mm (for EddySpot Desktop)

-

Thickness Range: unlimited

-

Material: carbon steel and its alloys

-

Surface Temperature: up to 600°C

Main Testing Parameters:

-

Reference Test Sensitivity: Hard Spots down to

10 x 10 mm are reliably detected -

Testing Speed: up to 2 m/s

-

Type of Applied Probes: Patented Multichannel EC probe