Automated Laser Geometry Measurement System for Plates, Strips and Slabs.

Dear Customers and Partners! We are glad to present you our new product!

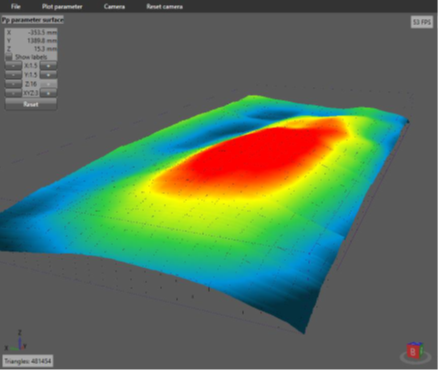

Equipment for Non-contact, Automated, Geometric Measurement of the Length, Flatness, Width, and Camber “GEOMETRIX-PL”, is designed to work in the technological flow of production of plates, sheets or slabs of steel, aluminum, brass, copper, etc.

The inspection of the material is carried out in a noncontact manner, in dynamic mode, directly on the process line on the existing mill roll line. This is made possible by the use of a modern measuring system, which includes precision mechanics, sets of laser 2-D profilometers, a calibration station, and a computer management system that implements extremely efficient algorithms for processing information flows.

System Essentials

- Measurement mode is automatic.

- Determining the maximum deviation from flatness of any type (concave, bulge, undulation, squareness), defined at a given meter of length or width of the sheet: ≤ ±1 mm/m;

- Determining the width of the product in the given part: ≤ ±1 mm;

- Definition of Camber, defined on one run meter of the edge: ≤ ±1 mm/m;

- In-line Wall thickness measurement;

- Measuring the speed-length of the roll: laser contactless.

- Work mode: continuous, designed for three shifts.

We proud to Inform you that GEOMETRIX-PL systems have already been put into operation at leading enterprises in Russia.

Soon we will post the full information of GEOMETRIX-PL, but for now don’t hesitate to contact us.