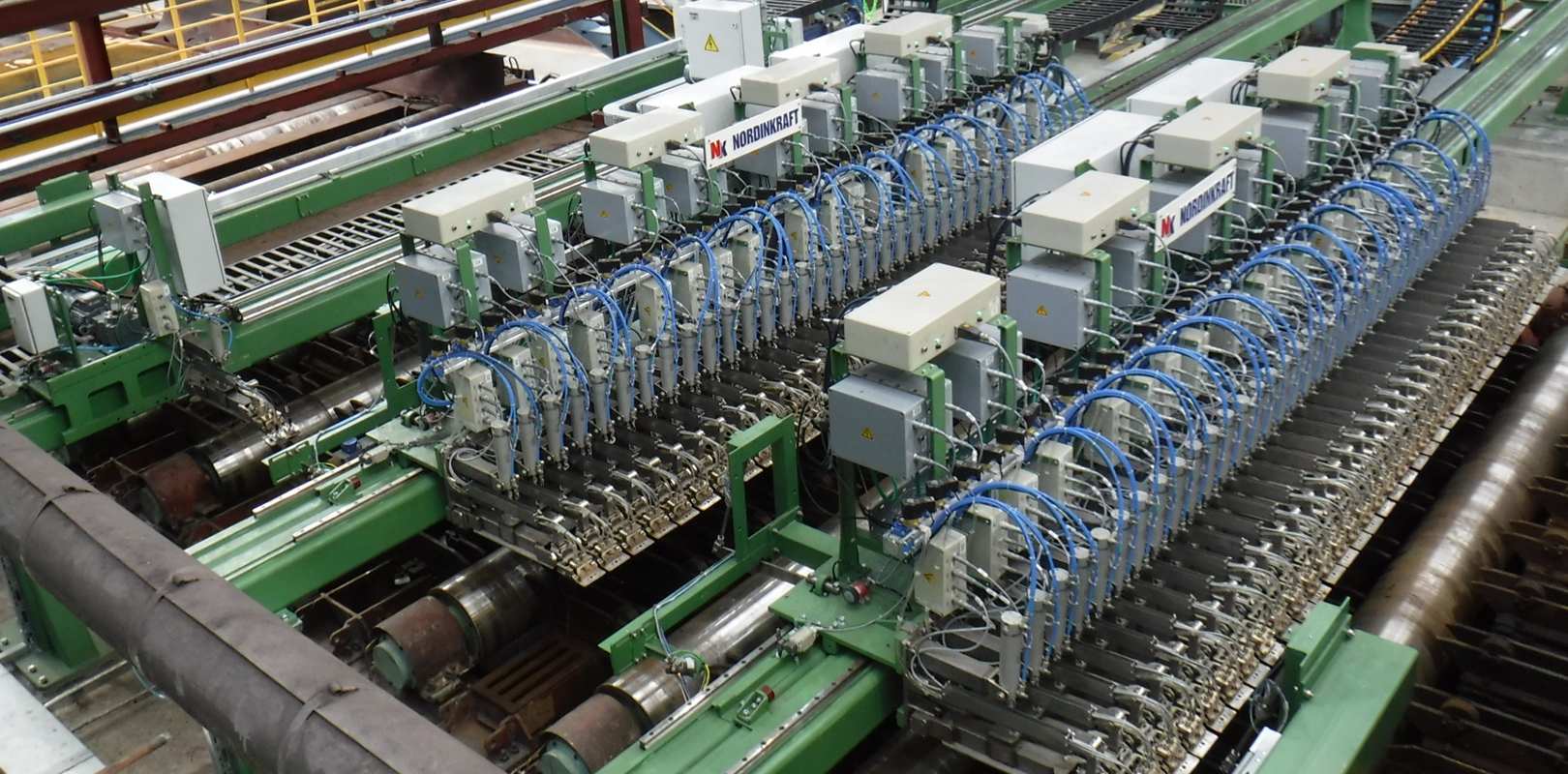

The EMATEST-PL is an innovative, fully automated, and in-line, nondestructive testing system.

EMATEST-PL performs material condition assessments in metallic plates, coils, welds, skelp, etc., using Ultrasonic, EMAT and/or Eddy current methods. 100% of production is inspected, providing valuable information for grading, quality inspection requirements, and process control data nearer to the process to reduce scrap rate caused by process related errors.

EMATEST-PL utilizes our advanced, intuitive, and operator friendly software for generating test results, displayed in the form of a defect map, in real time mode, and simultaneously saves the results on a local or external drive for further evaluation and analysis.

The EMATEST-PL is an innovative, fully automated, and in-line, nondestructive testing system.

EMATEST-PL performs material condition assessments in metallic plates, coils, welds, skelp, etc., using Ultrasonic, EMAT and/or Eddy current methods. 100% of production is inspected, providing valuable information for grading, quality inspection requirements, and process control data nearer to the process to reduce scrap rate caused by process related errors.

EMATEST-PL utilizes our advanced, intuitive, and operator friendly software for generating test results, displayed in the form of a defect map, in real time mode, and simultaneously saves the results on a local or external drive for further evaluation and analysis.

The EMATEST-PL series achieves multiple

inspection tasks:

- Detection of internal imperfections in rolled plates, ingots, and slabs such as: laminations, non-metallic inclusions, porosity, shell, sponge, etc.;

- Detection of surface and sub-surface defects;

- Detection of zones of mechanical properties uniformity (Hard Sports);

- Precise wall thickness measurement;

- Plate Geometry Monitoring.

Typical Specification of Plates to be Tested:

- Width: 100 mm – 6000 mm;

- Length: from 3000 mm;

- Thickness Range: 3 mm – 350 mm;

- Material: carbon steel;

- Surface Temperature: up to 600 deg. C.

Main Ultrasonic Testing Parameters

- Test Sensitivity:

- For internal imperfections: equal to FBH 2*;

- For surface imperfections: equal to notches 0.2 mm x 10 mm (D x W);

- Wall thickness measurement accuracy: +/- 0.05 mm;

- Testing Speed: up to 2 m/s.

*Depending of material to be tested

Ultrasonic Testing Standards:

Density of Ultrasonic examination, test procedures, acceptance criteria, data processing and representation adhere to multiple international and local standards such as: GOST 22727, SEL 072, ISO 12094, API 5L, ASTM 435, ASTM 578, DNV-OS-F101, EN10160, JIS0901, JIS0801, ISO10893, ISO3183

Testing and acceptance criteria can be customized based on client specific needs and new standards.

Type of Applied Multichannel Ultrasonic or Eddy Current probes

- Non-contact array probes, based on the EMAT;

- UT phase array probes;

- UT probes with the array of piezo-crystals;

- Eddy Current probes.